SPV DC

Maximum print speed, focusing on reducing handling times within fully automatic lines, is offered by the SPV-DC model. It is a screen print that has two print heads within a single machine and it is therefore possible to achieve a print time of 6.5 s per board in dual lane configuration. Usage is in high-capacity lines focused on mass production. For example, automatic paste refilling or paperless cleaning can also be used to streamline the automation process within the model.

| Category | Screen printers |

|---|---|

| Our solution | Inspection and production in SMT |

| Supplier | Panasonic Connect |

Main features and benefits of the device

- High efficiency dual lane production without changeovers

- Paperless cleaning function

- Automatic refill of solder paste

- Internal inspection for solder mask and final printing

Related categories

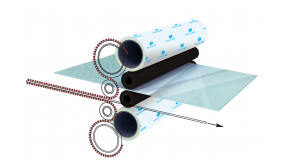

Welcome in the offer of high-tech, patented stencils for optimization of solder paste print by Christian Koenen. Thanks to our close cooperation...

We offer 3D SPI testers (Solder Paste Inspection) by a technological leader Koh Young. SPI testers are used to control the amount of the solder...

Welcome in the offer of offline and inline devices for contact cleaning from a European technological leader – Teknek. These devices are...

The Panasonic brand offers a wide range of SMT equipment for fitting components, but also for the THT process, with the two basic manufacturing...