SPV

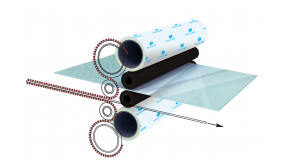

The SPV model is designed for medium and large-scale production, where the emphasis is not so much on flexibility, but rather on print speed. The print area is PCB up to 350×300 mm. The total cycle time of printing is for this model 10 s.

An essential part of the machine is also the possibility of setting the cleaning period of templates, both using conventional paper or the option of so-called paper-free cleaning, which reduces the cost of consumables.

| Category | Screen printers |

|---|---|

| Our solution | Inspection and production in SMT |

| Supplier | Panasonic Connect |

Main features and benefits of the device

- Designed for M PCB sizes

- High precision and fast printing (10 s per board)

- Suitable for mass production

- Automatic paste refill module

- Link to APC module

Related categories

Welcome in the offer of high-tech, patented stencils for optimization of solder paste print by Christian Koenen. Thanks to our close cooperation...

We offer 3D SPI testers (Solder Paste Inspection) by a technological leader Koh Young. SPI testers are used to control the amount of the solder...

Welcome in the offer of offline and inline devices for contact cleaning from a European technological leader – Teknek. These devices are...

The Panasonic brand offers a wide range of SMT equipment for fitting components, but also for the THT process, with the two basic manufacturing...