VCcount’s SMD counting machine XRHCount is in successful operation around the world. New customers can now benefit from various updates that make the machines more smart, reliable, and versatile.

As soon as the XRHCount arrives at a facility it is ready to use. The Plug and Play model is based on the basic premise that system teaching is not required because it already has a globally proven database stored locally. This results in no lost time to get the counting started. Furthermore, the machine still can use the established and valued Counting Cloud, but now can also work independently by implementing an offline version of it.

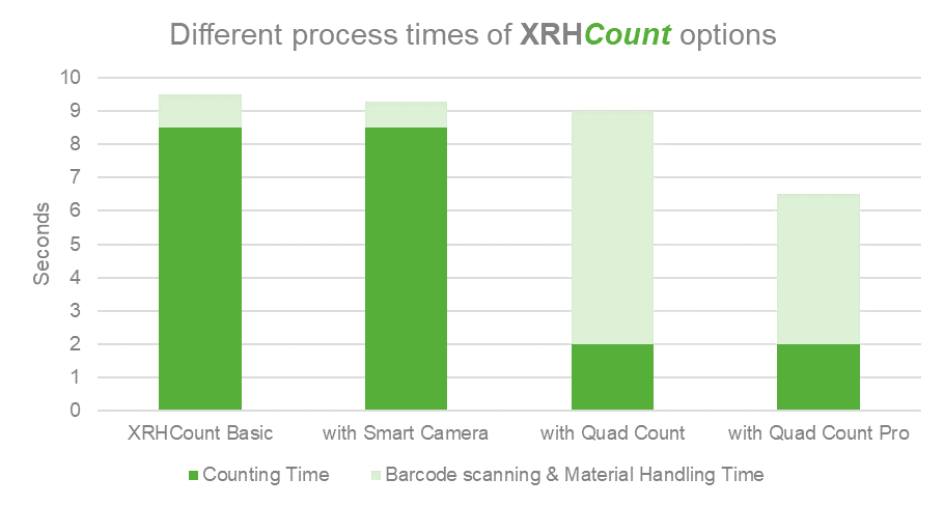

The cycle time is optimized via improved hardware and software. The new generation of the system is up to 20% faster and counts within 8.5 seconds per reel, and the Quad Count just needs 2 seconds per reel. The table shows the timings of the counting process: Drawer loading + component analysis + unloading.

Mechanically, the design of the drawer was optimized by a new concept using linear guides and lower weight, and maintenance time is reduced by implementing more access points for the service technician.

Vkládací šuplík byl mechanicky upraven a optimalizován za použití lineárního vedení a snížením váhy. Čas na údržbu je dále snížen umožněním přístupu technikovi z více míst.

Nejnovější verze software má nyní velmi intuitivní GUI, který byl vyvinut na základě zákaznických požadavků na dotykovou obrazovku.

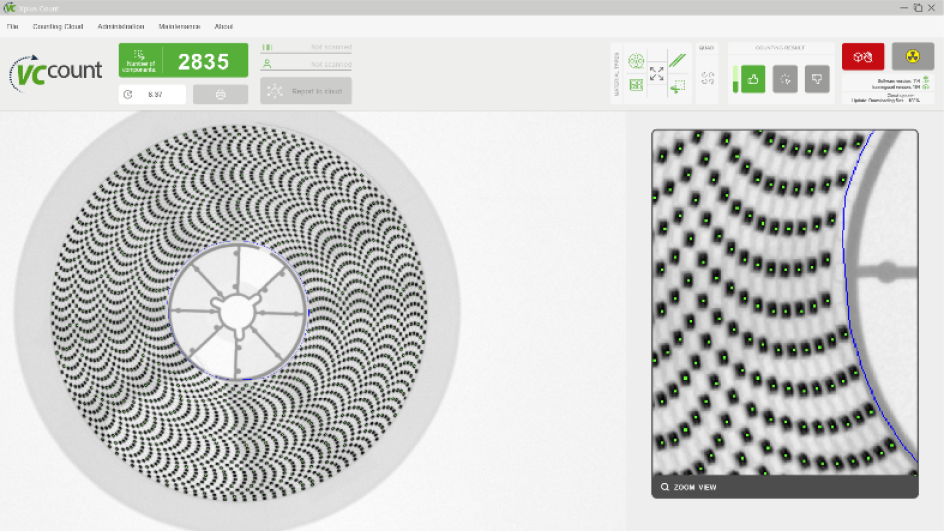

The newest software version has now a very intuitive user interface that was developed in correspondence to the customer’s request of a touch screen.

For smart industries the system is ready for robots, and the free Connectivity suite ensures an easy integration into the customer’s existing systems – now real-time data can be integrated to the facility’s ERP system or even be exported into a file based on usual industrial formats like XL, CSV, or TXT.