Single-purpose machines and production lines

Single-purpose machines and production lines from IMT are a key element of modern automation and robotization. We design and deliver turn-key modular lines to the your specific requirements – from simple assembly stations to complex fully automated systems equipped with PLC drivers, robots and industrial cameras. Our solutions increase productivity, ensure process‘ repeatability and reduce production costs.

| Category | Single-purpose machines |

|---|---|

| Our solution | Industrial automation |

| Supplier | IMT production |

We can do different variations of machines and workstations

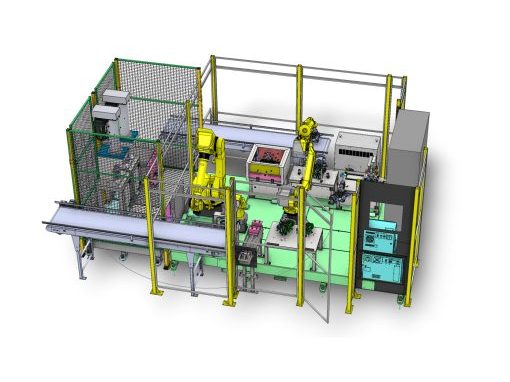

Complete automated lines for mass production. Connection of individual stations into an efficient unit. Flexible solutions for different products.

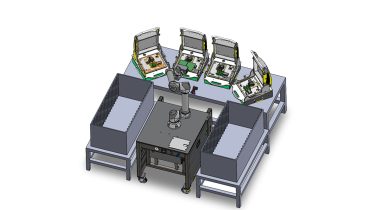

Equipment with rotating table for a smooth flow of production. High productivity in a small space. Ideal for variability for similar products.

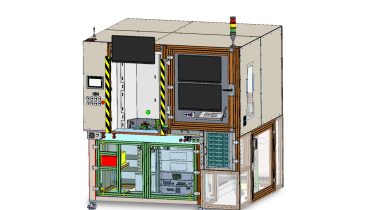

Stations for functional, electrical or other types of tests. Possibility of integrating third-party instruments or with our testers.

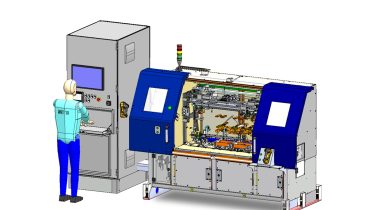

Machines integrated directly into a production line. Automatic control and processing of data during production. Minimising downtime and improving.

Robot / cobot integration for handling of products. Ideal for high variability of processed products. Also applicable for small-scale production.

Main benefits of machines from IMT

- Complete solutions from design to commissioning

- Construction and engineering facilities under one roof

- Tailored solutions to customer’s specific requirements

- Specialized service team for mechanical and software services

- Operator training and complete documentation

- Assembly hall for large lines of 800 m²

- Processing according to up-to-date standards and regulations

Application in a wide range of fields

Related categories

Collaborative robots (cobots) are designed to interact with humans in work environments. Their benefits include improving productivity, reducing...

Our imaging technology began with the visible spectrum, but today extends far beyond it, from deep infrared through deep UV and all the way...

AR (Augmented Reality) work instructions for smarter, safer, and more efficient processes on the factory floor and across your operations.

Inline handler from IMT is specially designed for inline electrical and functional testing of PCBs. The device is ready for contacting with...